Have you ever wondered what goes into repairing a precision clock? It’s a delicate process that requires specific tools and equipment to ensure the job is done correctly. In this guide, you will learn about advanced tools for precision clock repairs. So, let’s dive in and explore the world of clock repair!

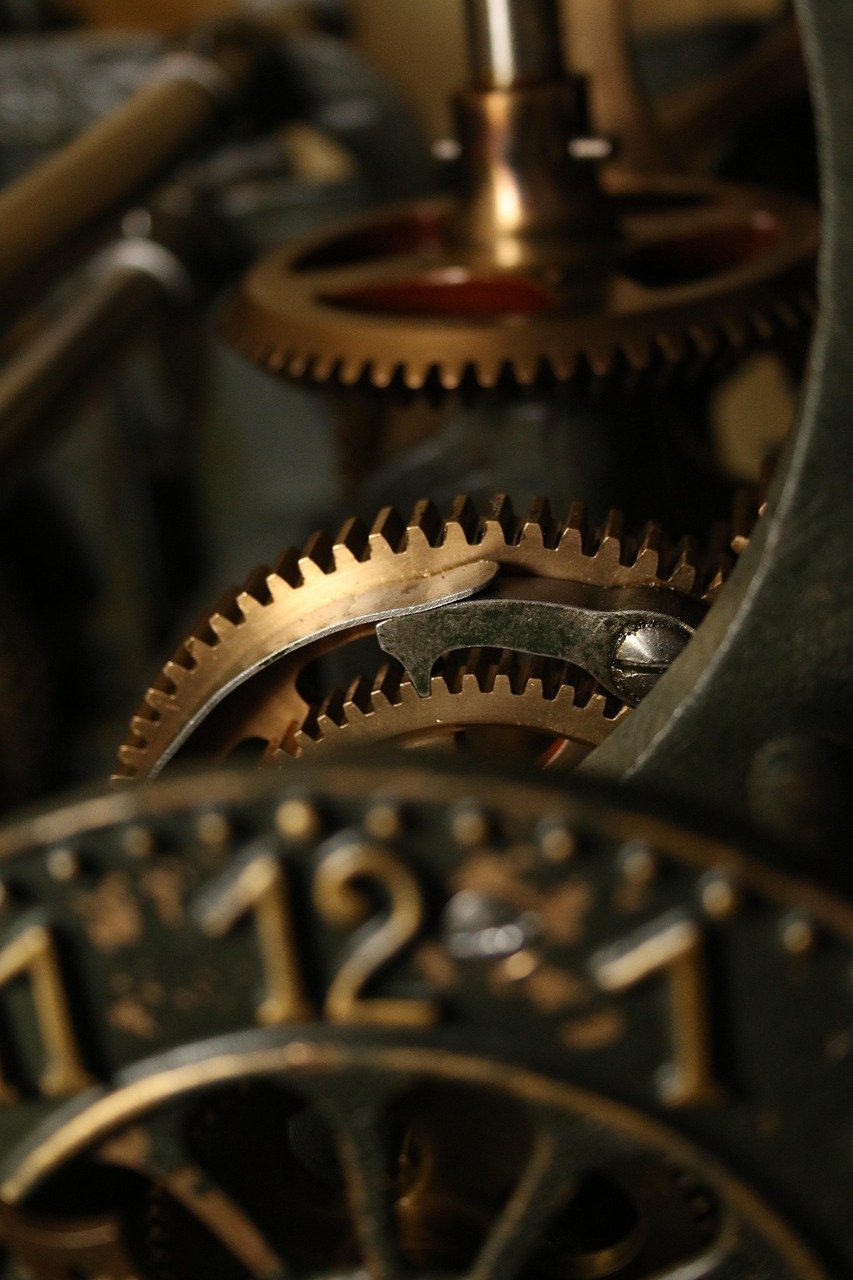

This image is property of pixabay.com.

Essential Tools for Clock Repair

When it comes to repairing clocks, having the right tools is essential. From removing hands to regulating the time, each tool serves a specific purpose in the repair process. Here are some essential tools you’ll need for precision clock repairs:

Clock Key

A clock key is a small, simple tool used to wind clocks with a key-wound mechanism. It’s important to have different sizes of clock keys to fit various types of clocks. Without a clock key, you won’t be able to wind the clock and keep it running accurately.

Screwdrivers

Screwdrivers are indispensable tools for clock repair. They are used to remove screws that hold the clock parts together. Clock repair requires precision, so having a set of screwdrivers with various sizes and shapes is crucial to avoid damaging delicate clock components.

Pliers

Pliers are versatile tools that come in handy for a variety of clock repair tasks. From bending metal to holding small parts in place, pliers are essential in handling delicate clock components without causing damage.

Tweezers

Tweezers are precision tools that are essential for handling tiny clock parts. They are used for delicate tasks such as placing screws, adjusting springs, and handling small gears. Having a set of tweezers with different tip shapes will make it easier to work on intricate clock mechanisms.

Polishing Cloths

Polishing cloths are essential for cleaning and polishing clock parts. They help remove dirt, dust, and tarnish from metal surfaces, restoring the clock’s appearance and functionality. Using a polishing cloth regularly will keep your clock looking its best and running smoothly.

Loupe

A loupe is a magnifying tool that allows you to see small details up close. It’s essential for inspecting tiny clock parts, identifying issues, and making precise adjustments. A high-quality loupe with a comfortable grip will make it easier to work on intricate clock mechanisms.

Oiler

An oiler is a specialized tool used to lubricate clock components for smooth operation. Proper lubrication is essential for ensuring the longevity and accuracy of a clock. Using the right type of oil and an oiler with a precise tip will help maintain your clock’s performance.

Specialized Tools for Advanced Clock Repairs

In addition to essential tools, advanced clock repairs may require specialized tools for more complex tasks. These tools are designed to handle intricate mechanisms and make precision adjustments. Here are some specialized tools that can take your clock repairs to the next level:

Bushing Tools

Bushing tools are used to create or repair worn pivot holes in clock plates. They come in various sizes and shapes to accommodate different types of clocks. Properly bushing a clock is a delicate process that requires precision tools to ensure a tight fit and smooth operation.

Pivot Polishers

Pivot polishers are specialized tools used to polish worn or damaged pivots on clock gears. They help restore the smooth surface of the pivot, allowing the gear to function properly and prevent wear over time. Using a pivot polisher will extend the lifespan of your clock’s mechanisms.

Escapement Tools

Escapement tools are essential for adjusting the escapement mechanism in a clock. They are used to regulate the movement of the clock hands and maintain accurate timekeeping. Properly adjusting the escapement requires specialized tools to ensure precise timing and smooth operation.

Mainspring Winder

A mainspring winder is a specialized tool used to wind and install mainsprings in clock movements. It’s designed to handle the tension of the mainspring and wind it evenly for optimal performance. Using a mainspring winder will make it easier to replace mainsprings and keep your clock running smoothly.

Balance Wheel Tools

Balance wheel tools are used to adjust the balance wheel in a clock movement. They are essential for regulating the movement of the balance wheel and maintaining accurate timekeeping. Properly adjusting the balance wheel requires precision tools to ensure precise timing and smooth operation.

This image is property of pixabay.com.

Maintenance Tips for Clock Repair Tools

Taking care of your clock repair tools is essential to ensure they perform optimally and last a long time. Proper maintenance will prevent rust, wear, and damage, keeping your tools in top condition for future repairs. Here are some maintenance tips to help you extend the lifespan of your clock repair tools:

Clean and Dry Tools After Use

After using your clock repair tools, make sure to clean them thoroughly to remove dirt, dust, and grime. Use a soft cloth to wipe down the tools and ensure they are free of debris. Once clean, make sure to dry the tools completely to prevent rust and corrosion.

Store Tools in a Dry Place

To prevent damage to your clock repair tools, store them in a dry place with low humidity. Moisture can cause rust and corrosion on metal tools, so it’s essential to keep them in a climate-controlled environment. Consider using a toolbox or case to keep your tools organized and protected.

Oil Moving Parts Regularly

For tools with moving parts, such as screwdrivers, pliers, and tweezers, it’s important to oil them regularly to keep them functioning smoothly. Use a light machine oil or lubricant to lubricate the moving parts and prevent wear. Proper lubrication will extend the lifespan of your tools and ensure they perform optimally.

Sharpen Cutting Tools

If your clock repair tools have cutting edges, such as screwdrivers and tweezers, make sure to sharpen them regularly to maintain their sharpness. A dull cutting edge can damage delicate clock components and make repairs more challenging. You can use a sharpening stone or file to sharpen the cutting edges of your tools.

Conclusion

In conclusion, having the right tools and equipment is essential for precision clock repairs. From essential tools like screwdrivers and tweezers to specialized tools like bushing tools and mainspring winders, each tool plays a specific role in the repair process. By following maintenance tips and caring for your tools properly, you can ensure they perform optimally and last a long time. So, the next time you need to repair a precision clock, make sure you have the right tools at your disposal for a successful repair. Happy repairing!